This article pertains to my ongoing MSc thesis in Sustainable Biotechnology, in which I am examining the role of bio-based plastics in the transition to a circular economy in Denmark. I am due to complete my Master’s in June 2021. In this article, I’ll be discussing the problem that I am examining in my thesis, as I am still gathering results.

You’ve heard it all before: the state of our plastic waste crisis is dire. And it’s true. Around 13 million tonnes of plastic leaks into the ocean annually, and this is just expected to increase unless we act now1. Of all of the plastic waste generated, the majority is plastic packaging, and constitutes 60% of the coastal waste2. So packaging is an interest focus area. When we zoom in on this fraction of plastic waste, it’s usually made up of polypropylene (PP), polyethylene (PE) and polyethylene terephthalate (PET). PET is one of the most widely used plastics, and also one of the most consumed. We use PET to make plastic bottles, and worldwide we consume about one million bottles every minute.

Linear and circular economies

One problem contributing to the plastic waste crisis is the way that we use things, which is in a very linear fashion. We take natural resources from the ground, we make a product, then we buy and use it, and then when we think we’re done with it, we just throw it away and never think about it again. But what happens to our waste? Well, in Denmark, we burn most of it for energy. When it comes to plastic, even though there are technology opportunities for the recycling of plastics, the traceability of this is quite low, and it’s still estimated that more than half of our plastics are incinerated2. While incineration is better than landfilling, it still results in a high amount of CO2 emissions, and it is the lowest value recovery option of plastics. Burning our waste and our linear systems results in a huge loss of potential. It is estimated that by not recycling plastics and having to import virgin plastic into Denmark, the country loses DKK 1.6 billion each year2.

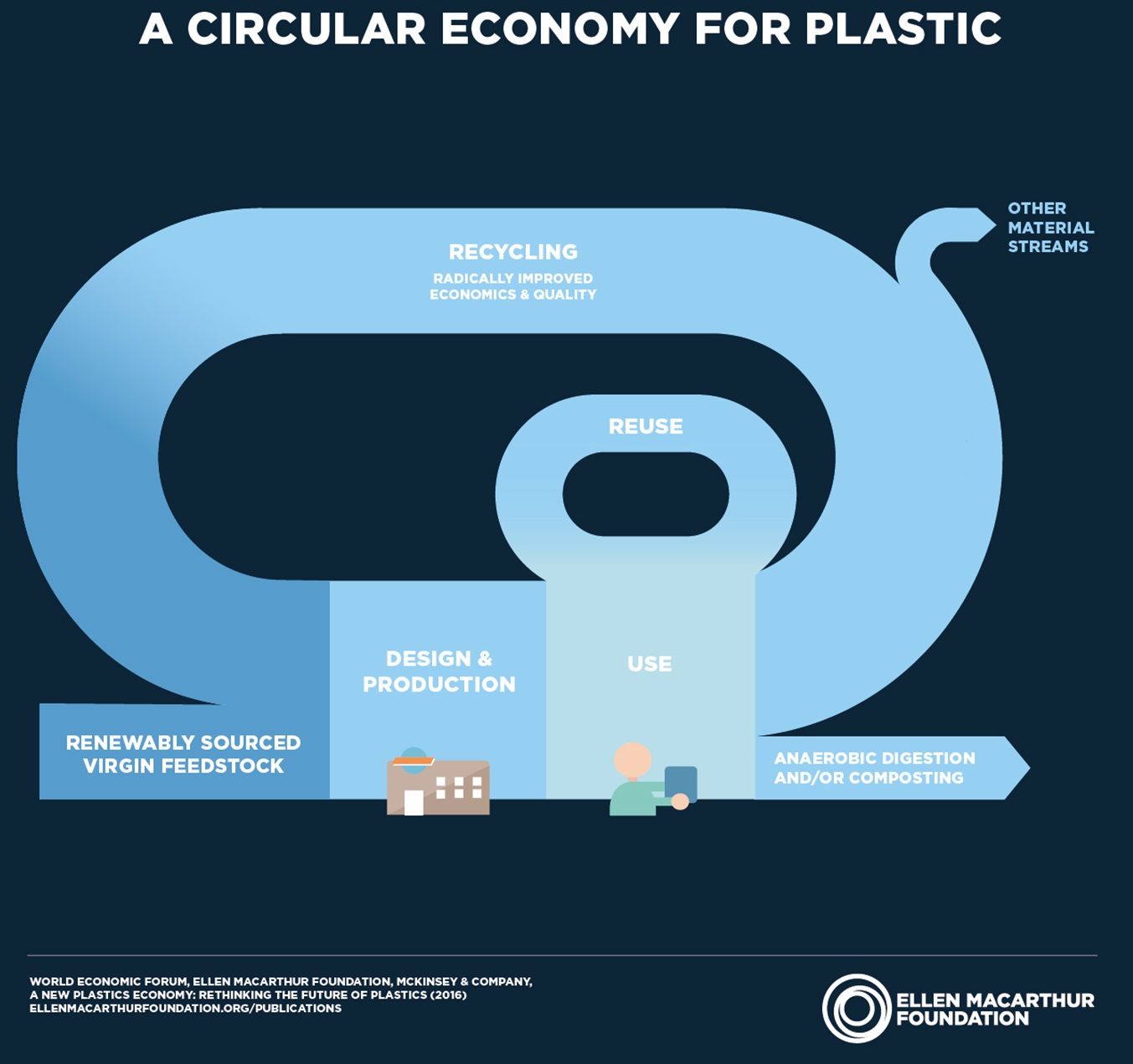

A different way of producing and consuming that is becoming increasingly popular is the concept of a circular economy. In an ideal circular economy, there is no real waste – things are designed to be used forever, and whatever isn’t used in one process for one product, may be used in another. We see this in nature, which is a system that has evolved over billions of years to sustain itself. In the circular economy, instead of throwing our waste away, we return it to the producers and it is either reused or recycled. An example of a somewhat circular system is the Dansk Retursystem.

Both on an EU-level and a national level, there is a movement from a linear system to a circular one. But to achieve a truly circular plastics economy, using renewable feedstock for new material is key.

Bio-based plastics – what are they?

Bio-based plastics are considered to play an important role in the transition to a circular plastic economy because they allow us to reduce our dependency on non-renewable feedstocks. The accepted definition of bio-based plastics, sometimes interchangeably referred to as bioplastics, is a plastic material made from renewable biomass sources. There are many different kinds of these plastics. There are some which are biodegradable, like polylactic acid (PLA) or polyhydroxyalkanoates (PHAs), but ‘bio-based’ does not necessarily mean ‘biodegradable’.

This confusion is quite dangerous because biodegradable plastic pollutes the plastic recycling stream, so we don’t want people throwing biodegradables away with recyclables. And ‘biodegradable’ often means biodegradable only under certain conditions, like elevated temperatures, which many people might not know. Even with the technology in place, we need to make sure we manage these sustainable innovations so that we optimise their environmental benefits.

Currently, bio-based plastics aren’t that big and represent only about 1% of the plastics market. However, there is investment by the European Commission, in a joint project with Bio-Based Industries (BBI), of 3.7 billion Euros to increase the production of bio-based raw materials. So bio-based plastics are soon become more present on the market – but is Denmark ready for them?

Working together to create change

We need to look both at the production of these plastics, as well as how they are handled, if we want to transition to a circular economy. Which is why my thesis topic is attempting to look at both of these aspects. Over the past few months, I have been conducting interviews with different stakeholders – people in policymaking, the plastic industry, waste management, and non-governmental organisations – about system-level strategies for bio-based plastic, in order to assess the readiness level of Denmark for the emergence of this material. Next, I’ll be conduct a citizen survey to better understand consumers’ perception of bio-based plastic. I’ll also be examining the production of a specific bio-based plastic that is an alternative to the widely used polyethylene terephthalate (PET). The intention behind this project is to contribute to the transition to a more circular economy in Denmark, and I’ll be sharing the results of the project in a few months’ time.

References

1. The PEW Charitable Trusts and SYSTEMIQ “Breaking the Plastic Wave” (2018) 2. McKinsey & Company “New Plastics Economy: A research, innovation and business opportunity for Denmark” (2019)

Megan Roux is a Master student of Sustainable Biotechnology, Aalborg University Copenhagen.

SUPPORT DDRN SCIENCE JOURNALISM. DONATE DKK 20 OR MORE![]() (APPLICABLE IN DENMARK ONLY)

(APPLICABLE IN DENMARK ONLY)